We areVulcano Metals

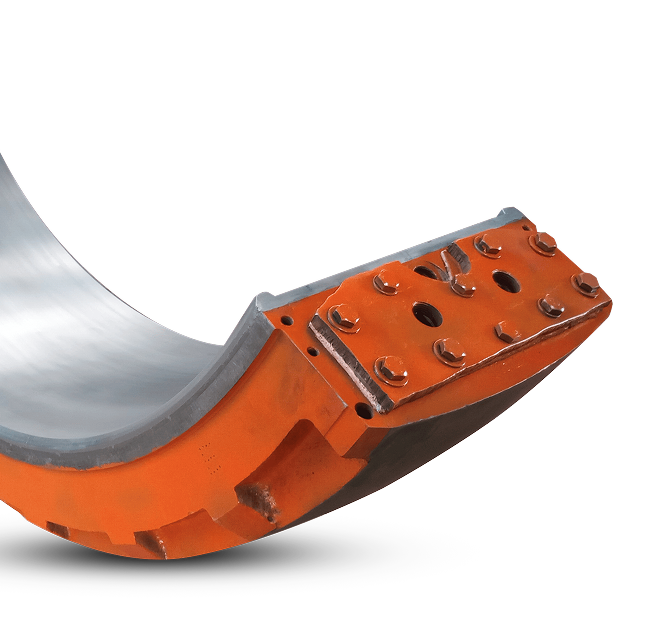

A metallurgical company specialized in the casting and manufacturing of bearings and parts made of bronze, brass, or babbitt for industrial machinery, following international technical standards and user specifications.

Our extensive knowledge and practical experience in the metallurgy of these alloys, combined with investments in state-of-the-art machine tools, enable us to produce reliable bearings and parts capable of withstanding the most demanding applications in modern industry.

Our value proposition

To be leaders in the manufacturing of bearings and parts made of Bronze, Brass, and Babbitt with superior quality, committed to continuous improvement, the sustainability of our production processes, and the generation of value for our customers, shareholders, and collaborators.

2003

Vulcano Metals was established in 2003 as Metalúrgica Vulcano, with the objective of manufacturing and supplying high-quality bearings and parts made of Bronze, Brass, and Babbitt to the general industry.

2008

Since 2008, we have been exporting—initially to companies in Ecuador—and later expanding our market with regular shipments to Chile, the United States, Colombia and Panama.

2011

Since 2011, we have progressively equipped our foundry, machining, and quality control areas with high-capacity horizontal and vertical centrifugal casting machines, modern CNC machinery, and digital control and micro-measurement equipment and instruments.

2018

In 2018, we changed our company name to VULCANO METALS S.A.C. and registered our trademark with the Distinctive Signs Directorate of the National Institute for the Defense of Competition and Protection of Intellectual Property – INDECOPI.

We guarantee our commitment to quality and safety under ISO certifications

Since 2022, our Integrated Management System has been certified with ISO 9001:2015 for Quality and ISO 45001:2018 for Occupational Health and Safety, ensuring the quality of our manufactured products in safe and healthy working environments.

We are a socially sustainable company

Acting with ethics and in harmony with our social, economic, and environmental surroundings

We align productive evolution and development with human quality of life by implementing the sustainable Circular Economy model in our operations. We manufacture bearings and components with superior quality, extended service life, and minimal replacement cycles. We use raw materials, supplies, and energy efficiently, aiming for their Reduction, Reuse, Recycling, and the environmentally safe disposal of final waste.

We reuse depleted materials (scrap, by-products, and waste from Copper, Bronze, Brass, and Babbitt) through chemical composition classification and melting into ingots, which are then reintroduced into the casting process along with pure materials, until the required chemical and mechanical specifications of each alloy are met.