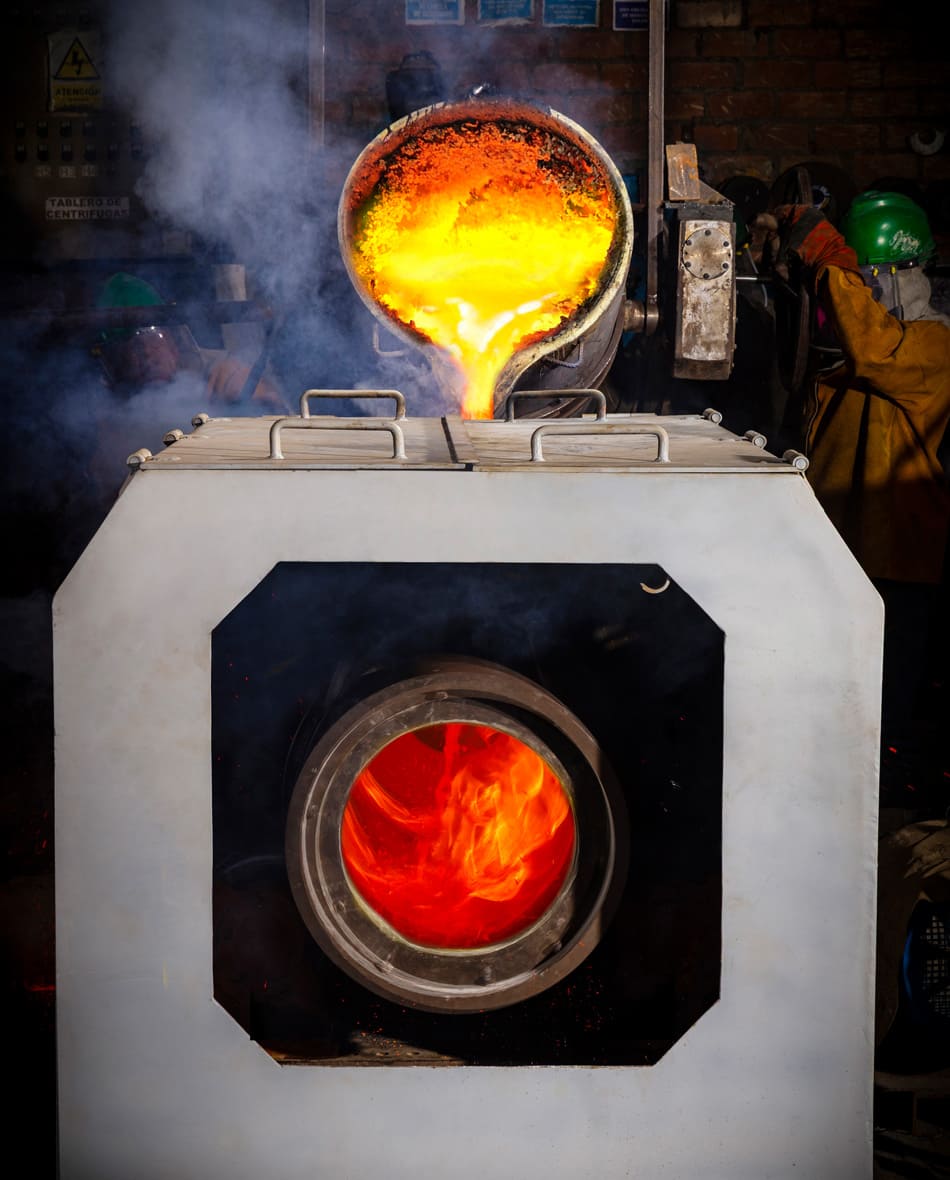

Foundry

We developed our own casting know-how, including pouring, nucleation rate, and directional cooling, aimed at controlling atomic ordering and grain size of the alloys. Likewise, we set the %Ni, %Sn, and other alloying elements at the upper range of the Technical Standard to maximize mechanical properties without compromising their antifriction qualities.

Equipment

We have four furnaces with capacities of 250, 450, 800, and 1200 kg, allowing us to cast bearings and parts ranging from less than 1 kg up to 1200 kg. We use centrifugal casting techniques on horizontal and vertical machines, producing more than 1800 sizes of bearings, rings, hubs, and tubular parts with radial symmetry, within the following dimensional ranges:

- External diameter: 30 to 1500 mm

- Length: 20 to 2000 mm

- Minimum wall thickness: 4 mm

Centrifugal casting

Referred to as forged from a liquid metal, it consists of pouring molten bronze or brass into metal matrices that are rotating at high speeds so that the centrifugal force propels it and distributes it uniformly in its cavity, displacing gases and impurities towards the inner diameter; those that are removed in the first roughing.

The great force “G” released on the metal (60 times more than standard gravity) combined with rapid external water cooling, facilitates progressive unidirectional solidification toward the axis of rotation, obtaining parts with:

- Prolonged service life due to its uniform molecular structure, fine and compact grain;

- free of oxides, segregations and non-metallic inclusions.

- Equal mechanical properties in all directions (isotropic structure), which is not the case

- in forging, rolling, or extrusion processes.

- Yield strength, elongation, tensile strength, impact, wear, fatigue, excessive loads and

- other mechanical/physical properties; up to 30% greater compared to static casting

- methods.

- High sealability and thermal stability at very high pressures.

Static casting

Due to its irregular shapes, special geometries and/or large size, a large number of pieces; along with tin bronzes with high Pb content (antifriction), cannot be centrifuged, so they are cast by gravity in sand molds (using self-setting synthetic resins or the CO system2) and the rotary casting method.

- Inventory of molds and designs of regularly manufactured parts.

- Metal boxes for molding and sand casting the different pieces.

- 5-ton bridge crane.

- Immersion pyrometer to control casting temperature.

- Molding sand mixer.

- General tools and equipment.

Babbitt casting

White, babbitt, or anti friction metals are mixtures of Tin, Antimony, Copper, and Lead, with additions of other metals in some alloys. They are produced by dissolving the alloying metals to the point where they exceed the solubility limit, causing the formation of hard, dispersed crystals within the soft and plastic mass of the base metal. The number, size, distribution, and type of crystals formed depend on the amount of alloying elements, the melting, casting techniques, and cooling speed; these factors constitute the microstructure, which is crucial for the varying mechanical and anti friction properties of different types of babbitt.

A babbitt bearing must primarily support weight and provide a non-damaging surface for the shaft. It must also have a sufficient elastic limit to prevent general deformation while being low enough to allow local alterations. It should exhibit high resistance to fatigue, cyclic stresses, and avoid distortion, mechanical failure, or corrosion. Additionally, when lubrication is contaminated or fails, the babbitt (the softer alloy) will wear out instead of the shaft.

Next manufacturing process